A primer on pumps

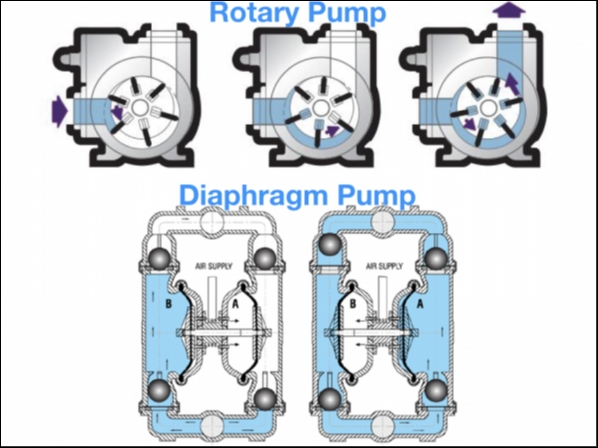

For years, the standard pump in the industry has been the internal gear pump, also known as a rotary gear positive displacement pump. At the single facers and at the glue machine, where these pumps are used to return the excess starch from the glue pans to the storage tanks, they are typically 2-inch pumps with a capacity of 35 to 40 gallons per minute.

In the starch preparation area, where they are used to feed the starch into the supply loop to the corrugator and to transfer starch from the mixer to the storage tanks, they are typically also 2-inch models but with a capacity of 90 to100 gallons per minute.

To prevent pump damage and motor overloads as the result of blockages, these pumps should be equipped with a bypass relief valve.

The advantage of this style pump is that it delivers a constant flow at constant pressure. Disadvantages include the maintenance required to maintain the packing and the breakdown in viscosity caused by the shearing action.

Whichever option you choose, it is imperative to have a good preventive maintenance system in place, as well as spare pumps with the necessary connections in place to make possible a rapid changeover, if needed.

Often we find that the root cause of a flow or delivery problem is really a blockage or restriction in the pipe rather than a pump problem.